Table of Contents

Advantages of Using Modern Lifting Equipment for Port Operations

In the fast-paced world of port operations, efficiency and safety are paramount. With the increasing demand for goods to be transported across the globe, ports are constantly looking for ways to streamline their processes and improve productivity. One way that ports can achieve this is by investing in modern lifting equipment.

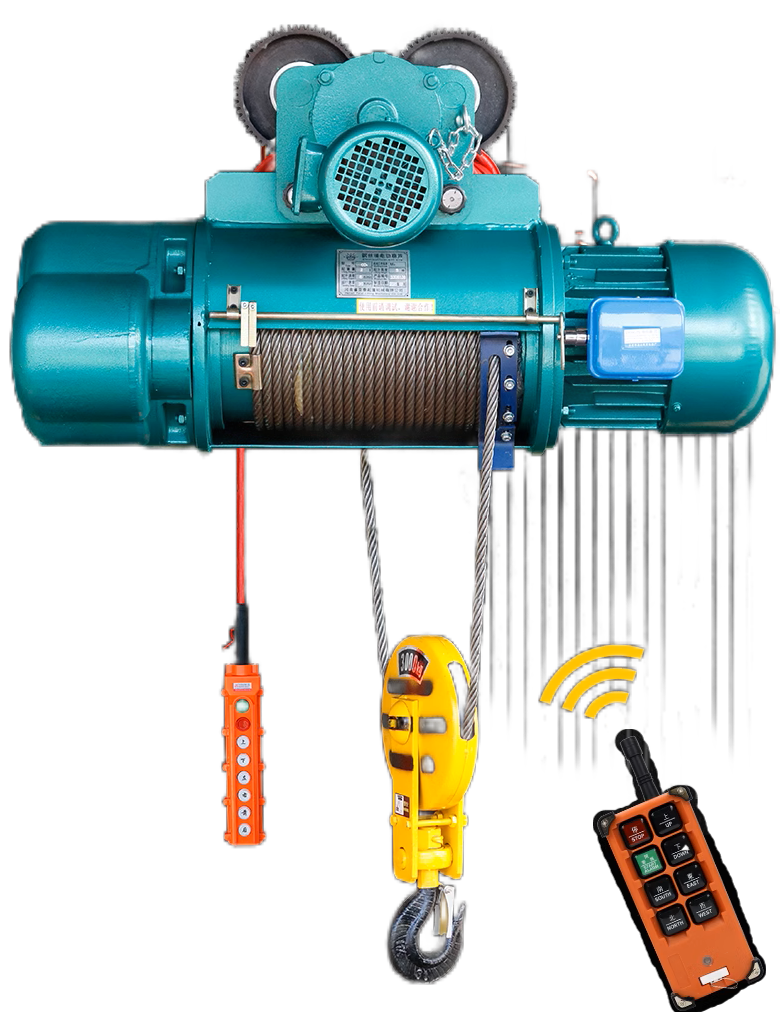

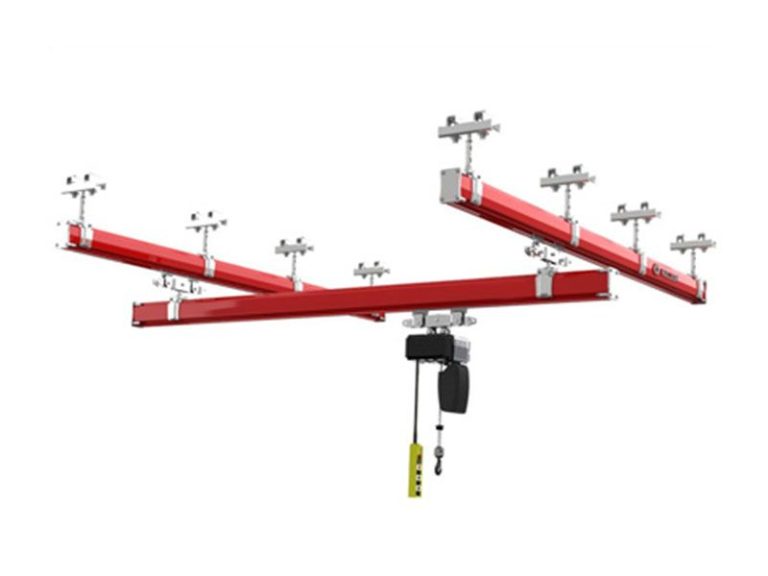

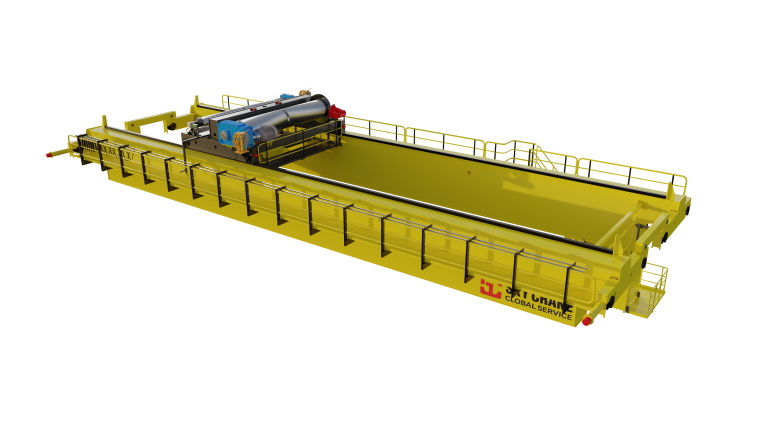

Modern lifting equipment, such as cranes and forklifts, offer a wide range of advantages for port operations. These advanced machines are designed to handle heavy loads with precision and speed, making them essential tools for moving cargo from ships to storage facilities and vice versa.

One of the key advantages of using modern lifting equipment in ports is the increased efficiency they provide. These machines are capable of lifting and moving heavy loads quickly and safely, reducing the time it takes to unload and load ships. This means that ports can handle more cargo in a shorter amount of time, leading to increased productivity and profitability.

In addition to efficiency, modern lifting equipment also improves safety in port operations. These machines are equipped with advanced safety features, such as sensors and alarms, to prevent accidents and injuries. By using modern lifting equipment, ports can create a safer working environment for their employees and reduce the risk of costly accidents.

| No. | Product |

| 1 | European electric single beam |

| 2 | Rail – mounted Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Another advantage of using modern lifting equipment in ports is the versatility they offer. These machines come in a variety of sizes and configurations, allowing ports to choose the equipment that best suits their needs. Whether it’s a large crane for unloading ships or a small forklift for moving cargo around the storage yard, modern lifting equipment can be tailored to fit the specific requirements of each port.

Furthermore, modern lifting equipment is designed to be more environmentally friendly than traditional methods of cargo handling. These machines are powered by clean energy sources, such as electricity or natural gas, reducing emissions and minimizing the impact on the environment. By investing in modern lifting equipment, ports can demonstrate their commitment to sustainability and reduce their carbon footprint.

In conclusion, the advantages of using modern lifting equipment for port operations are clear. From increased efficiency and safety to versatility and environmental sustainability, these machines offer a wide range of benefits for ports looking to improve their operations. By investing in modern lifting equipment, ports can streamline their processes, increase productivity, and create a safer working environment for their employees. With the global demand for goods continuing to rise, modern lifting equipment is becoming an essential tool for ports looking to stay competitive in the industry.

Safety Measures and Regulations for Lifting Equipment in Ports

Lifting equipment plays a crucial role in the operations of ports around the world. From loading and unloading cargo to moving containers and heavy machinery, these machines are essential for the efficient functioning of port facilities. However, the use of lifting equipment also poses significant risks to workers and the surrounding environment if not properly managed. Therefore, it is essential for port operators to adhere to strict safety measures and regulations to ensure the safe operation of lifting equipment in ports.

One of the most important safety measures for lifting equipment in ports is regular inspection and maintenance. All lifting equipment should be inspected by qualified personnel on a regular basis to ensure that it is in good working condition. Any defects or malfunctions should be promptly addressed to prevent accidents and injuries. Additionally, routine maintenance should be carried out to keep the equipment in optimal condition and prevent breakdowns.

Another crucial safety measure for lifting equipment in ports is proper training for operators. Operating lifting equipment requires specialized skills and knowledge, and operators should undergo thorough training before being allowed to operate such machinery. Training should cover topics such as equipment operation, safety procedures, and emergency protocols. Regular refresher courses should also be provided to ensure that operators are up to date with the latest safety regulations and best practices.

In addition to regular inspection, maintenance, and training, ports should also adhere to strict regulations governing the use of lifting equipment. These regulations are put in place to ensure the safety of workers and the surrounding environment. Port operators should familiarize themselves with these regulations and ensure that they are fully compliant at all times. Failure to comply with regulations can result in fines, penalties, and even the suspension of operations.

One of the key regulations governing the use of lifting equipment in ports is the requirement for proper documentation. All lifting equipment should have up-to-date documentation, including inspection reports, maintenance records, and operator certifications. This documentation should be readily available for inspection by regulatory authorities to ensure that the equipment is being properly maintained and operated.

Another important regulation for lifting equipment in ports is the requirement for safety devices and features. All lifting equipment should be equipped with safety devices such as overload protection, emergency stop buttons, and warning alarms. These devices are designed to prevent accidents and injuries by alerting operators to potential hazards and stopping the equipment in case of an emergency.

In conclusion, the safe operation of lifting equipment in ports is essential for the efficient functioning of port facilities and the protection of workers and the environment. By adhering to strict safety measures and regulations, port operators can ensure that lifting equipment is operated safely and effectively. Regular inspection, maintenance, training, and compliance with regulations are key components of a comprehensive safety program for lifting equipment in ports. By prioritizing safety, port operators can prevent accidents, injuries, and costly downtime, ultimately leading to a more productive and sustainable port operation.

Latest Technological Innovations in Lifting Equipment for Port Makers

Lifting equipment plays a crucial role in the operations of ports around the world. From loading and unloading cargo to moving containers and heavy machinery, efficient and reliable lifting equipment is essential for the smooth functioning of port facilities. In recent years, there have been significant advancements in the design and technology of lifting equipment for port makers, leading to increased efficiency, safety, and productivity.

One of the latest technological innovations in lifting equipment for port makers is the development of automated container handling systems. These systems use advanced robotics and artificial intelligence to streamline the process of loading and unloading containers from ships, trucks, and trains. By automating these tasks, port operators can significantly reduce the time and labor required to handle containers, leading to faster turnaround times and increased throughput.

Another key innovation in lifting equipment for port makers is the use of remote-controlled cranes and gantry systems. These systems allow operators to control lifting equipment from a safe distance, reducing the risk of accidents and injuries. Remote-controlled cranes also enable operators to work more efficiently, as they can easily adjust the position and angle of the crane without having to physically climb into the cab.

In addition to automation and remote control, advancements in sensor technology have also had a significant impact on the design of lifting equipment for port makers. Sensors can be used to monitor the weight, position, and stability of loads, providing operators with real-time data to ensure safe and efficient lifting operations. By incorporating sensors into lifting equipment, port makers can minimize the risk of accidents and damage to cargo, while also optimizing the performance of their equipment.

Furthermore, the integration of Internet of Things (IoT) technology into lifting equipment has revolutionized the way port operators manage and maintain their equipment. IoT-enabled lifting equipment can be connected to a central monitoring system, allowing operators to track the performance and condition of their equipment in real-time. This data can be used to schedule maintenance and repairs proactively, reducing downtime and extending the lifespan of the equipment.

Overall, the latest technological innovations in lifting equipment for port makers have transformed the way ports operate, leading to increased efficiency, safety, and productivity. By incorporating automation, remote control, sensor technology, and IoT connectivity into their lifting equipment, port operators can streamline their operations, reduce costs, and improve overall performance.

In conclusion, the future of lifting equipment for port makers is bright, with continued advancements in technology driving innovation and improvement in the industry. As ports continue to expand and handle larger volumes of cargo, the demand for efficient and reliable lifting equipment will only continue to grow. By staying at the forefront of technological developments, port makers can ensure that their operations remain competitive and sustainable in the ever-evolving global marketplace.