Table of Contents

Advantages of Customized European Electric Single Beam Crane for Factory Requirements

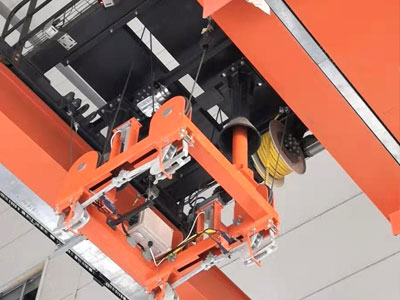

In the industrial sector, the use of cranes is essential for lifting and moving heavy loads with precision and efficiency. One type of crane that is commonly used in factories is the European electric single beam crane. This type of crane is known for its reliability, durability, and versatility in handling various types of loads. However, not all factories have the same requirements when it comes to crane operations. That is why many factories opt for customized European electric single beam cranes that are tailored to their specific needs.

One of the main advantages of customizing a European electric single beam crane for factory requirements is that it ensures optimal performance and efficiency. By customizing the crane according to the specific needs of the factory, it can be designed to handle the exact load capacities, lifting heights, and operating speeds required for the job. This not only improves productivity but also ensures the safety of workers and equipment in the factory.

Another advantage of customizing a European electric single beam crane is that it can be tailored to fit the layout and space constraints of the factory. Every factory has its own unique layout and space limitations, which can impact the installation and operation of a crane. By customizing the crane, it can be designed to fit perfectly within the available space, maximizing the use of the factory floor and minimizing any disruptions to other operations.

Furthermore, customizing a European electric single beam crane allows for the integration of advanced features and technologies that can enhance its performance and functionality. For example, the crane can be equipped with smart controls, automation systems, and safety features that make it easier to operate and maintain. These advanced features not only improve the efficiency of crane operations but also reduce the risk of accidents and downtime in the factory.

In addition, customizing a European electric single beam crane allows for the incorporation of specific accessories and attachments that are needed for the job. Whether it is a specialized lifting attachment, a custom-designed hook, or a unique control system, these accessories can be added to the crane to meet the specific requirements of the factory. This level of customization ensures that the crane is fully equipped to handle the tasks at hand, no matter how complex or demanding they may be.

Overall, customizing a European electric single beam crane for factory requirements offers numerous benefits that can significantly improve the efficiency, safety, and productivity of crane operations. By tailoring the crane to the specific needs of the factory, it ensures optimal performance, seamless integration, and enhanced functionality. With advanced features, smart controls, and specialized accessories, a customized crane can meet the most demanding requirements of any factory, making it an indispensable tool for lifting and moving heavy loads with precision and ease.

Key Considerations for Designing a Tailored European Electric Single Beam Crane for Factory Use

When it comes to selecting the right equipment for a factory, one of the most important considerations is the type of crane that will be used for lifting and moving heavy loads. European electric single beam cranes are a popular choice for many factories due to their efficiency, reliability, and versatility. These cranes are designed to meet the specific needs of each individual factory, making them an ideal solution for a wide range of applications.

One of the key considerations when designing a tailored European electric single beam crane for factory use is the weight capacity that will be required. It is essential to accurately assess the maximum weight of the loads that will need to be lifted in order to ensure that the crane is capable of handling them safely and efficiently. This information will help determine the size and specifications of the crane, as well as the type of hoist and trolley that will be needed.

In addition to weight capacity, the height and span of the crane must also be taken into account. The height of the crane will depend on the height of the factory building and the maximum height at which loads will need to be lifted. The span of the crane refers to the distance between the runway rails, and it is important to ensure that the crane can cover the entire working area of the factory. By carefully considering these factors, the crane can be customized to fit the specific layout and requirements of the factory.

Another important consideration when designing a European electric single beam crane for factory use is the type of control system that will be used. There are various options available, including pendant controls, radio controls, and cabin controls, each with its own advantages and disadvantages. The control system must be selected based on the specific needs of the factory, taking into account factors such as operator comfort, ease of use, and safety.

Safety is a top priority when designing a crane for factory use, and there are several features that can be incorporated to ensure the safety of both operators and equipment. These may include overload protection, emergency stop buttons, limit switches, and anti-collision devices. By carefully considering these safety features during the design process, the crane can be customized to meet the highest safety standards and provide peace of mind for all those working in the factory.

| No. | Products |

| 1 | LD electric single beam crane |

| 2 | Rail – mounted Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Finally, it is important to consider the maintenance and service requirements of the crane when designing a tailored European electric single beam crane for factory use. Regular maintenance is essential to ensure the continued performance and longevity of the crane, and it is important to select a crane that is easy to maintain and service. By working closely with a reputable crane manufacturer, factory owners can ensure that their crane is designed to be durable, reliable, and easy to maintain for years to come.

In conclusion, designing a tailored European electric single beam crane for factory use requires careful consideration of a variety of factors, including weight capacity, height and span, control system, safety features, and maintenance requirements. By working closely with a reputable crane manufacturer, factory owners can ensure that their crane is customized to meet their specific needs and provide efficient and reliable lifting solutions for their operations.