Table of Contents

Benefits of Using Lifting Equipment in Factory Operations

Lifting equipment plays a crucial role in factory operations, helping to streamline processes, improve efficiency, and ensure the safety of workers. As factories continue to evolve and modernize, the demand for high-quality lifting equipment has never been greater. Chinese suppliers have emerged as leaders in the industry, offering a wide range of lifting solutions that are both reliable and cost-effective.

One of the key benefits of using lifting equipment in factory operations is the ability to increase productivity. By automating the lifting process, workers can focus on other tasks, leading to a more efficient workflow. This not only saves time but also reduces the risk of human error, ultimately improving the overall quality of the products being produced.

In addition to improving productivity, lifting equipment also plays a crucial role in ensuring the safety of workers. Manual lifting can be physically demanding and can lead to injuries if not done properly. By using lifting equipment, workers can avoid strain and injury, creating a safer work environment for everyone involved. This not only protects the well-being of employees but also reduces the risk of costly workplace accidents.

Furthermore, lifting equipment can help factories maximize their space and storage capacity. By utilizing vertical space for storage and transportation, factories can make the most of their available square footage. This can lead to increased efficiency and cost savings, as less space is required to store materials and finished products.

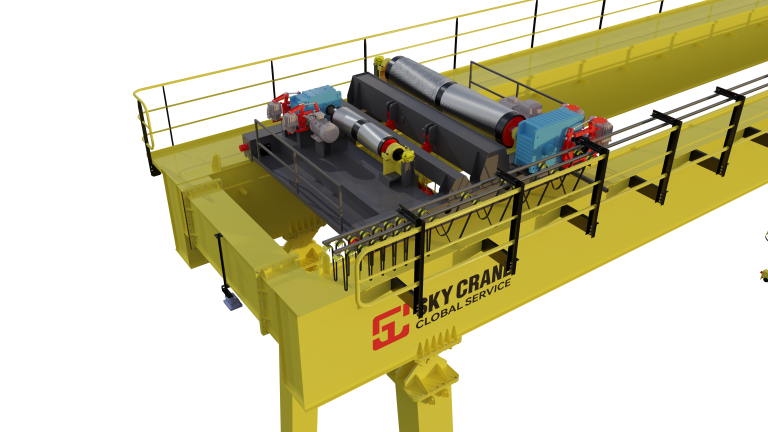

Chinese suppliers are known for their high-quality lifting equipment, offering a wide range of options to suit the needs of any factory. From overhead cranes to pallet jacks, Chinese suppliers have a solution for every lifting requirement. Their products are not only reliable but also cost-effective, making them an attractive option for factories looking to improve their operations without breaking the bank.

Another benefit of using lifting equipment in factory operations is the ability to handle heavy loads with ease. Manual lifting of heavy objects can be dangerous and inefficient, leading to potential injuries and delays in production. By using lifting equipment, factories can safely and efficiently move heavy loads, reducing the risk of injury and improving overall productivity.

| No. | Product |

| 1 | 5~400T NEW-TYPE OVERHEAD CRANE WITH HOOK |

| 2 | Double – girder Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

In conclusion, lifting equipment is an essential component of modern factory operations, offering a wide range of benefits that can help improve efficiency, safety, and productivity. Chinese suppliers have emerged as leaders in the industry, offering high-quality lifting solutions that are both reliable and cost-effective. By investing in lifting equipment from Chinese suppliers, factories can streamline their operations, protect their workers, and maximize their space and storage capacity. Ultimately, lifting equipment is a valuable asset for any factory looking to stay competitive in today’s fast-paced manufacturing environment.

Top Considerations When Choosing a Chinese Supplier for Lifting Equipment

When it comes to choosing a Chinese supplier for lifting equipment for factories, there are several key considerations that must be taken into account. With the growing demand for high-quality lifting equipment in the manufacturing industry, it is crucial to select a reliable and reputable supplier that can provide the necessary equipment to meet your specific needs.

One of the most important factors to consider when choosing a Chinese supplier for lifting equipment is the quality of the products they offer. It is essential to ensure that the equipment meets all necessary safety standards and regulations to prevent accidents and injuries in the workplace. Look for suppliers that have a proven track record of providing high-quality lifting equipment that is durable and reliable.

In addition to quality, it is also important to consider the range of products offered by the supplier. Different factories may have varying lifting requirements, so it is essential to choose a supplier that can provide a wide range of lifting equipment to meet your specific needs. Whether you need overhead cranes, hoists, or lifting accessories, make sure the supplier can offer a comprehensive selection of products to choose from.

Another crucial consideration when selecting a Chinese supplier for lifting equipment is the level of customer service and support they provide. A reliable supplier should be able to offer assistance with installation, maintenance, and repairs to ensure that your lifting equipment operates efficiently and safely. Look for suppliers that have a dedicated customer service team that can provide timely and helpful support whenever needed.

Cost is also an important factor to consider when choosing a Chinese supplier for lifting equipment. While it is essential to find a supplier that offers competitive pricing, it is equally important to ensure that the equipment is of high quality and meets all necessary safety standards. Avoid suppliers that offer significantly lower prices than their competitors, as this may indicate subpar quality or lack of proper certifications.

When selecting a Chinese supplier for lifting equipment, it is also crucial to consider the supplier’s reputation and experience in the industry. Look for suppliers that have a solid reputation for providing high-quality products and excellent customer service. Additionally, consider the supplier’s experience in the industry and their track record of delivering reliable lifting equipment to factories.

Lastly, it is essential to consider the supplier’s location and logistics capabilities when choosing a Chinese supplier for lifting equipment. Ensure that the supplier can provide timely delivery of the equipment to your factory and has the necessary logistics infrastructure in place to support your needs. Consider factors such as shipping costs, lead times, and import/export regulations when selecting a supplier to ensure a smooth and efficient procurement process.

In conclusion, choosing a Chinese supplier for lifting equipment for factories requires careful consideration of several key factors. From quality and range of products to customer service and cost, it is essential to select a supplier that can meet your specific needs and provide reliable and high-quality lifting equipment. By taking the time to research and evaluate potential suppliers, you can ensure that you find a reputable and reliable partner for all your lifting equipment needs.

Safety Measures and Regulations for Operating Lifting Equipment in Factories

Lifting equipment plays a crucial role in the operations of factories, allowing for the efficient movement of heavy materials and products. However, the use of lifting equipment also poses significant risks to the safety of workers if not operated properly. In order to ensure the safe operation of lifting equipment in factories, it is important to adhere to strict safety measures and regulations.

One of the most important safety measures when operating lifting equipment in factories is proper training for all employees involved in the operation of the equipment. Workers should be trained on how to safely operate the equipment, as well as how to identify and respond to potential hazards. This training should be ongoing, with regular refresher courses to ensure that all employees are up to date on the latest safety protocols.

In addition to proper training, it is also important to regularly inspect and maintain lifting equipment to ensure that it is in good working condition. This includes checking for any signs of wear and tear, as well as ensuring that all safety features are functioning properly. Regular maintenance can help prevent accidents and prolong the lifespan of the equipment.

When operating lifting equipment in factories, it is also important to follow all relevant safety regulations and guidelines. This includes ensuring that the equipment is used within its specified capacity limits, as overloading can lead to equipment failure and accidents. It is also important to follow proper lifting techniques, such as using the appropriate attachments and securing loads properly.

Another important safety measure when operating lifting equipment in factories is to ensure that the work area is clear of obstacles and that there is adequate space for the equipment to operate safely. This includes ensuring that there are no overhead obstructions that could interfere with the movement of the equipment, as well as ensuring that there is enough space for the equipment to maneuver without coming into contact with other objects.

In addition to these safety measures, it is also important to have a comprehensive safety plan in place in case of an emergency. This plan should outline procedures for responding to accidents or malfunctions, as well as protocols for evacuating the area if necessary. All employees should be familiar with the safety plan and know how to respond in the event of an emergency.

By following these safety measures and regulations, factories can ensure the safe operation of lifting equipment and protect the well-being of their employees. Proper training, regular maintenance, adherence to safety regulations, and a comprehensive safety plan are all essential components of a safe working environment when operating lifting equipment in factories. By prioritizing safety, factories can prevent accidents and injuries, and create a safer and more efficient workplace for all employees.