Table of Contents

Port operatsiyalari uchun zamonaviy yuk ko’tarish uskunasidan foydalanishning afzalliklari

Yo’q.

| Mahsulot | Yevropa elektr bitta nur |

| 1 | Temir yo’lga o’rnatilgan portalli kran |

| 2 | Yevropa uslubidagi kran |

| 3 | Liman krani |

| 4 | Portlarda zamonaviy yuk ko’tarish uskunalaridan foydalanishning yana bir afzalligi – ular taklif qiladigan ko’p qirrali. Ushbu mashinalar turli o’lcham va konfiguratsiyalarga ega bo’lib, portlarga o’z ehtiyojlariga eng mos keladigan uskunani tanlash imkonini beradi. Kemalarni tushirish uchun katta kran yoki yuklarni saqlash hovlisi bo’ylab tashish uchun kichik forklift bo’ladimi, zamonaviy yuk ko’tarish uskunalari har bir portning o’ziga xos talablariga mos ravishda moslashtirilishi mumkin.

Bundan tashqari, zamonaviy yuk ko’tarish uskunalari ekologik jihatdan qulayroq bo’lishi uchun yaratilgan. yuklarni tashishning an’anaviy usullari. Ushbu mashinalar elektr yoki tabiiy gaz kabi toza energiya manbalari bilan ishlaydi, chiqindilarni kamaytiradi va atrof-muhitga ta’sirini kamaytiradi. Zamonaviy yuk ko’tarish uskunalariga sarmoya kiritib, portlar barqarorlikka sodiqligini namoyish etishi va uglerod izini kamaytirishi mumkin. Xulosa qilib aytganda, port operatsiyalari uchun zamonaviy yuk ko’tarish uskunalaridan foydalanishning afzalliklari aniq. Samaradorlik va xavfsizlikni oshirishdan ko’p qirralilik va ekologik barqarorlikka qadar, bu mashinalar o’z faoliyatini yaxshilashga intilayotgan portlar uchun keng ko’lamli imtiyozlarni taklif etadi. Zamonaviy yuk ko’tarish uskunalariga sarmoya kiritib, portlar o’z jarayonlarini soddalashtirishi, mahsuldorlikni oshirishi va o’z xodimlari uchun xavfsizroq ish muhitini yaratishi mumkin. Tovarlarga bo’lgan global talab o’sishda davom etar ekan, zamonaviy yuk ko’tarish uskunalari sanoatda raqobatbardosh bo’lishni xohlaydigan portlar uchun muhim vositaga aylanmoqda. |

Portlarda yuk ko’tarish uskunalari uchun xavfsizlik choralari va qoidalari

Port ishlab chiqaruvchilar uchun yuk ko’tarish uskunalaridagi so’nggi texnologik innovatsiyalar

Ko’tarish uskunalari butun dunyo bo’ylab portlar faoliyatida hal qiluvchi rol o’ynaydi. Yuklarni yuklash va tushirishdan tortib, harakatlanuvchi konteynerlar va og’ir texnikalargacha samarali va ishonchli yuk ko’tarish uskunalari port inshootlarining uzluksiz ishlashi uchun juda muhimdir. So’nggi yillarda port ishlab chiqaruvchilar uchun yuk ko’tarish uskunalarini loyihalash va texnologiyasida sezilarli yutuqlarga erishildi, bu esa samaradorlik, xavfsizlik va mahsuldorlikni oshirishga olib keldi.

Port ishlab chiqaruvchilari uchun yuk ko’tarish uskunalaridagi eng so’nggi texnologik yangiliklardan biri bu avtomatlashtirilgan qurilmalarni ishlab chiqishdir. konteynerlarni tashish tizimlari. Bu tizimlar kemalar, yuk mashinalari va poyezdlardan konteynerlarni yuklash va tushirish jarayonini soddalashtirish uchun ilg‘or robototexnika va sun’iy intellektdan foydalanadi. Ushbu vazifalarni avtomatlashtirish orqali port operatorlari konteynerlarga ishlov berish uchun zarur bo’lgan vaqt va mehnatni sezilarli darajada qisqartirishi mumkin, bu esa tezroq ishlash muddati va o’tkazish qobiliyatini oshiradi.

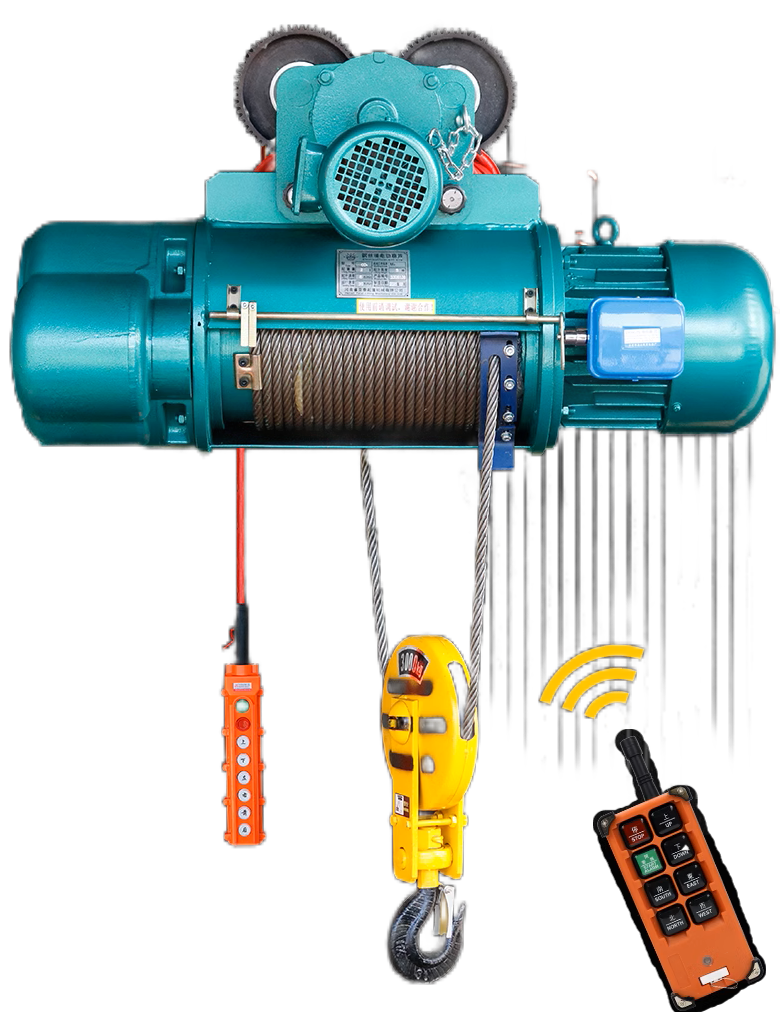

Port ishlab chiqaruvchilar uchun yuk ko’tarish uskunalaridagi yana bir muhim yangilik masofadan boshqariladigan kranlar va portal tizimlaridan foydalanish hisoblanadi. . Ushbu tizimlar operatorlarga yuk ko’tarish moslamalarini xavfsiz masofadan boshqarish imkonini beradi, baxtsiz hodisalar va jarohatlar xavfini kamaytiradi. Masofadan boshqariladigan kranlar, shuningdek, operatorlarga yanada samarali ishlash imkonini beradi, chunki ular kranning joylashuvi va burchagini kabinaga jismoniy ko‘tarilmasdan osongina sozlashi mumkin.

Avtomatlashtirish va masofadan boshqarishdan tashqari, sensorlar texnologiyasidagi yutuqlar ham mavjud. port ishlab chiqaruvchilari uchun yuk ko’tarish uskunalari dizayniga sezilarli ta’sir ko’rsatadi. Datchiklar yuklarning og’irligi, holati va barqarorligini kuzatish uchun ishlatilishi mumkin, bu esa operatorlarni xavfsiz va samarali ko’tarish operatsiyalarini ta’minlash uchun real vaqtda ma’lumotlar bilan ta’minlaydi. Datchiklarni yuk ko‘tarish uskunasiga kiritish orqali port ishlab chiqaruvchilari avariyalar va yuklarga zarar yetkazish xavfini minimallashtirishi, shu bilan birga o‘z jihozlarining ishlashini optimallashtirishi mumkin.

Bundan tashqari, Internet of Things (IoT) texnologiyasining yuk ko‘tarish uskunasiga integratsiyalashuvi yo‘lda inqilob qildi. port operatorlari jihozlarini boshqaradi va ularga xizmat ko’rsatadi. IoT-ni qo’llab-quvvatlaydigan yuk ko’tarish uskunalari markaziy monitoring tizimiga ulanishi mumkin, bu esa operatorlarga real vaqt rejimida o’z uskunalarining ishlashi va holatini kuzatish imkonini beradi. Ushbu ma’lumotlardan texnik xizmat ko’rsatish va ta’mirlashni proaktiv rejalashtirish, ishlamay qolish vaqtini qisqartirish va uskunaning ishlash muddatini uzaytirish uchun ishlatilishi mumkin.

Umuman olganda, port ishlab chiqaruvchilar uchun yuk ko’tarish uskunalaridagi so’nggi texnologik yangiliklar portlarning ishlash usulini o’zgartirib, samaradorlik, xavfsizlik, va hosildorlik. Avtomatlashtirish, masofadan boshqarish, sensor texnologiyasi va IoT ulanishini yuk ko’tarish uskunalariga kiritish orqali port operatorlari o’z operatsiyalarini soddalashtirishi, xarajatlarni kamaytirishi va umumiy ish faoliyatini yaxshilashi mumkin.

Xulosa qilib aytganda, port ishlab chiqaruvchilar uchun yuk ko’tarish uskunalarining kelajagi porloq. sanoatda innovatsiyalar va takomillashtirishga turtki bo’lgan texnologiya sohasidagi davomiy yutuqlar. Portlar kengayishda va katta hajmdagi yuklarni tashishda davom etar ekan, samarali va ishonchli yuk ko’tarish uskunalariga talab faqat o’sishda davom etadi. Texnologik o’zgarishlarning oldingi safida bo’lish orqali port ishlab chiqaruvchilari o’z operatsiyalari doimiy rivojlanayotgan global bozorda raqobatbardosh va barqaror bo’lishini ta’minlashi mumkin.

Latest Technological Innovations in Lifting Equipment for Port Makers

Lifting equipment plays a crucial role in the operations of ports around the world. From loading and unloading cargo to moving containers and heavy machinery, efficient and reliable lifting equipment is essential for the smooth functioning of port facilities. In recent years, there have been significant advancements in the design and technology of lifting equipment for port makers, leading to increased efficiency, safety, and productivity.

One of the latest technological innovations in lifting equipment for port makers is the development of automated container handling systems. These systems use advanced robotics and artificial intelligence to streamline the process of loading and unloading containers from ships, trucks, and trains. By automating these tasks, port operators can significantly reduce the time and labor required to handle containers, leading to faster turnaround times and increased throughput.

Another key innovation in lifting equipment for port makers is the use of remote-controlled cranes and gantry systems. These systems allow operators to control lifting equipment from a safe distance, reducing the risk of accidents and injuries. Remote-controlled cranes also enable operators to work more efficiently, as they can easily adjust the position and angle of the crane without having to physically climb into the cab.

In addition to automation and remote control, advancements in sensor technology have also had a significant impact on the design of lifting equipment for port makers. Sensors can be used to monitor the weight, position, and stability of loads, providing operators with real-time data to ensure safe and efficient lifting operations. By incorporating sensors into lifting equipment, port makers can minimize the risk of accidents and damage to cargo, while also optimizing the performance of their equipment.

Furthermore, the integration of Internet of Things (IoT) technology into lifting equipment has revolutionized the way port operators manage and maintain their equipment. IoT-enabled lifting equipment can be connected to a central monitoring system, allowing operators to track the performance and condition of their equipment in real-time. This data can be used to schedule maintenance and repairs proactively, reducing downtime and extending the lifespan of the equipment.

Overall, the latest technological innovations in lifting equipment for port makers have transformed the way ports operate, leading to increased efficiency, safety, and productivity. By incorporating automation, remote control, sensor technology, and IoT connectivity into their lifting equipment, port operators can streamline their operations, reduce costs, and improve overall performance.

In conclusion, the future of lifting equipment for port makers is bright, with continued advancements in technology driving innovation and improvement in the industry. As ports continue to expand and handle larger volumes of cargo, the demand for efficient and reliable lifting equipment will only continue to grow. By staying at the forefront of technological developments, port makers can ensure that their operations remain competitive and sustainable in the ever-evolving global marketplace.