Table of Contents

Benefits of Using YH Type Metallurgical Electric Hoists in Industrial Applications

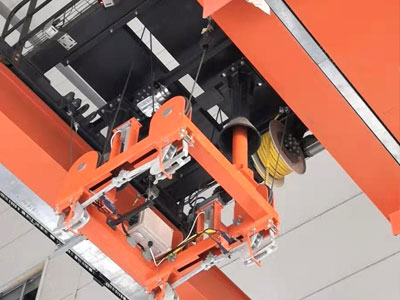

YH Type Metallurgical Electric Hoists are essential tools in various industrial applications due to their efficiency, reliability, and safety features. These hoists are specifically designed to meet the demanding requirements of metallurgical industries, making them ideal for lifting and moving heavy loads in harsh environments. In this article, we will explore the benefits of using YH Type Metallurgical Electric Hoists in industrial applications.

| Nr. | Commodity Name |

| 1 | General purpose bridge crane |

| 2 | Rubber – tired Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

One of the key advantages of YH Type Metallurgical Electric Hoists is their high lifting capacity. These hoists are capable of lifting heavy loads with ease, making them suitable for handling large and bulky materials in industrial settings. Whether it’s moving raw materials in a steel mill or transporting finished products in a manufacturing plant, YH Type Metallurgical Electric Hoists can handle the job efficiently and effectively.

In addition to their impressive lifting capacity, YH Type Metallurgical Electric Hoists are also known for their durability and reliability. These hoists are built to withstand the rigors of daily use in industrial environments, ensuring that they can perform consistently and reliably over time. This reliability is crucial in industrial applications where downtime can be costly and disruptive to operations.

Another benefit of using YH Type Metallurgical Electric Hoists is their safety features. These hoists are equipped with various safety mechanisms to prevent accidents and ensure the well-being of workers. From overload protection to emergency stop buttons, YH Type Metallurgical Electric Hoists are designed with safety in mind, providing peace of mind to operators and workers alike.

Furthermore, YH Type Metallurgical Electric Hoists are easy to operate and maintain, making them user-friendly and cost-effective. With simple controls and minimal maintenance requirements, these hoists are ideal for busy industrial environments where efficiency is key. Operators can quickly and easily learn how to use YH Type Metallurgical Electric Hoists, reducing training time and increasing productivity.

Additionally, YH Type Metallurgical Electric Hoists are versatile and can be customized to meet specific requirements. Whether it’s adjusting the lifting capacity, speed, or control options, these hoists can be tailored to suit the needs of different industrial applications. This flexibility makes YH Type Metallurgical Electric Hoists a valuable asset in a wide range of industries.

Overall, YH Type Metallurgical Electric Hoists offer numerous benefits for industrial applications, including high lifting capacity, durability, reliability, safety features, ease of operation, and versatility. These hoists are essential tools for handling heavy loads in demanding environments, making them a valuable investment for any industrial operation.

In conclusion, YH Type Metallurgical Electric Hoists are an indispensable asset in industrial applications due to their efficiency, reliability, and safety features. With their high lifting capacity, durability, and user-friendly design, these hoists are well-suited for handling heavy loads in a variety of industrial settings. Whether it’s moving materials in a steel mill or transporting products in a manufacturing plant, YH Type Metallurgical Electric Hoists are the ideal solution for lifting and moving heavy loads with ease and precision.

Maintenance Tips for YH Type Metallurgical Electric Hoists

YH Type Metallurgical Electric Hoists are essential equipment in various industries, including mining, construction, and manufacturing. These hoists are designed to lift and move heavy loads with precision and efficiency. To ensure the longevity and optimal performance of your YH Type Metallurgical Electric Hoist, regular maintenance is crucial. In this article, we will discuss some maintenance tips to help you keep your hoist in top condition.

One of the most important maintenance tasks for YH Type Metallurgical Electric Hoists is regular inspection. Inspecting the hoist for any signs of wear and tear, such as frayed cables or loose bolts, can help prevent accidents and ensure the safety of your workers. It is recommended to inspect the hoist before each use and to schedule regular maintenance checks by a qualified technician.

Another crucial maintenance tip for YH Type Metallurgical Electric Hoists is lubrication. Proper lubrication of the hoist’s moving parts, such as the gears and bearings, can help reduce friction and wear, extending the hoist’s lifespan. It is important to use the manufacturer-recommended lubricants and to follow the recommended lubrication schedule to ensure optimal performance.

In addition to regular inspection and lubrication, it is important to keep the hoist clean. Dust, dirt, and debris can accumulate on the hoist’s components, causing them to wear out faster. Regularly cleaning the hoist with a soft brush or cloth can help prevent this buildup and keep the hoist running smoothly.

Furthermore, it is important to check the hoist’s electrical components regularly. Inspecting the wiring, switches, and controls for any signs of damage or malfunction can help prevent electrical issues and ensure the hoist’s safe operation. If you notice any problems with the electrical components, it is important to have them repaired by a qualified technician as soon as possible.

Proper storage of the YH Type Metallurgical Electric Hoist is also essential for its maintenance. Storing the hoist in a clean, dry environment away from extreme temperatures and humidity can help prevent corrosion and damage to the hoist’s components. It is also important to store the hoist in a secure location to prevent theft or unauthorized use.

Lastly, it is important to follow the manufacturer’s maintenance guidelines and recommendations for your YH Type Metallurgical Electric Hoist. These guidelines are designed to help you keep your hoist in top condition and ensure its safe and efficient operation. By following these tips and guidelines, you can extend the lifespan of your hoist and prevent costly repairs and downtime.

In conclusion, regular maintenance is essential for keeping your YH Type Metallurgical Electric Hoist in top condition. By following these maintenance tips, you can ensure the safety, efficiency, and longevity of your hoist. Remember to inspect the hoist regularly, lubricate its moving parts, keep it clean, check its electrical components, store it properly, and follow the manufacturer’s maintenance guidelines. With proper maintenance, your YH Type Metallurgical Electric Hoist will continue to serve you well for years to come.